As a leading perfume packaging manufacturer, all lids have perfect compatibility with industry-standard bottle Mouth sizes, work with many well-known brands, such as Dior, Guerlain, Ikea, Lancome, Muji, Dolce & Gabbana, Paul & Shark, Lattafa, REEF, Arabian Oud, EMPER, AFNAN, LAVERNE, ROJA, AL MAJID, ALEXANDRE.J, and so on, also Upgraded Premium Packaging for 5000+ Emerging Startups and Growing Niche Fragrance Brands.

Technical Specifications & Performance Standards

| Parameter | Specification Details | Testing Method / Standard |

|---|---|---|

| Compatibility | Compatible with standard 13.5mm, 15mm, 18mm, 20mm, and 24mm bottle finishes. Custom neck fits available. | Dimensional verification per ISO 11040 for glass bottle finishes. |

| Thread / Snap-Fit Tolerance | Thread pitch tolerance: ±0.1mm. Snap-fit interference: 0.2-0.4mm for secure, non-binding seal. | Coordinate Measuring Machine (CMM) inspection. |

| Magnetic Strength | Neodymium N35-N52 grade magnets. Pull force: 8-12 Newtons (adjustable per client requirement). | Digital force gauge testing (ASTM D6195). |

| Alcohol & Solvent Resistance | All inner liners (LDPE, silicone) pass 90-day immersion tests with 95% ethanol and fragrance oils. | Accelerated aging test per ISO 283; zero cracking, swelling, or deformation. |

| Durability & Lifecycle | Rated for 10,000+ open/close cycles without significant force degradation (>15% change). | Automated cycle testing per ASTM D2063. |

| Surface Finish Durability | PVD coating: >100 hours salt spray test; Electroplating: >48 hours salt spray test. | ASTM B117 neutral salt spray test. |

| Material Safety & Compliance | All materials comply with EU REACH, FDA 21 CFR, and Proposition 65 for heavy metals. | Third-party lab reports (SGS, Intertek) available. |

Custom Design Zamac & Zinc Alloy Caps & Lids Manufacturer for Perfume Bottles

Design and Customize Zamac & zinc alloy caps & Lids for perfume bottles according to your design file or ideas, from classic luxury to modern fashion, to communicate instant luxury through substantial weight and flawless, intricate finishes, to offer unparalleled design freedom to create a unique and iconic cap that becomes a signature brand element.

This page only shows our ability to implement your idea and turn your design into a true bottle lid and caps. The following pictures are not for you to choose a design, they are to showcase the craft requirements my team can achieve.

China Custom Design Natural Jade Stone Perfume Bottle Cap Manufacturer Supplier

Customize different sizes, colors, and shapes of jade stone and resin materials, according to your designs and ideas, connecting your brand to positive energy and holistic well-being, resonating deeply with modern consumers’ interest in mindfulness and self-care.

China Custom Design Natural Marble Stone Perfume Bottle Cap Manufacturer Supplier

Customize different sizes, colors, and shapes of natural marble according to your designs and ideas, evoke a narrative of timeless elegance, heritage, and natural artistry, and offer an authentic, one-of-a-kind luxury, where no two lids are exactly alike, appealing to consumers seeking exclusivity.

Customize Wooden Perfume Bottle Cap And Stopper Manufacturers China

The wooden perfume caps manufacturer customises any size and shape according to your design and idea, making each lid a unique artwork, bringing a warm, natural, and artisanal quality that stands out in a market of synthetic materials,often use Wax wood, oak, shea wood, bamboo.

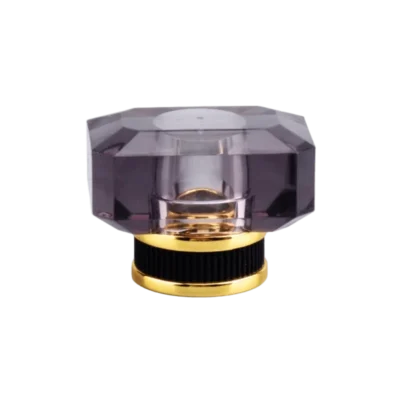

China Customize Acrylic PETG Plastic PP Volcanic Rock Perfume Bottle Lid Manufacturer And Stopper

The wooden perfume caps manufacturer customizes any size and shape according to your design and idea, making each lid a unique artwork, bringing a warm, natural, and artisanal quality that stands out in a market of synthetic materials.

Ordering, Logistics & Customization

| Aspect | Details |

|---|---|

| Minimum Order Quantity (MOQ) | Standard Stock Designs: 1,000 pcs. Custom Designs: 1,000 – 10,000 pcs, depending on material and decoration complexity. |

| Lead Time | Standard Caps: 7-10 business days. Custom & New Tooling Caps: 15-25 business days. Expedited options available. |

| Packaging | Standard: Polybag individual wrap, packed in inner cartons and master export cartons. Custom velvet pouches, inserts, or blister packs available. |

| Pricing Range | Varies widely by material, size, and decoration. Pricing Reference: ……….. |

| Confidentiality (NDA) | All private custom design projects with a comprehensive, legally binding Non-Disclosure Agreement (NDA) to protect intellectual property. |

Frequently Asked Questions (FAQ)

Q1: How do I ensure your caps will fit my existing bottles?

A: We require the exact outer diameter and thread specification (or finish type) of your bottle neck. The best practice is to send 3-5 physical bottle samples. We will perform a dimensional analysis and produce fitting samples for your approval, ensuring a perfect seal and user experience.

Q2: Can you match a specific Pantone color or a physical sample?

A: Absolutely. We specialize in color matching. Please provide the Pantone code or a physical sample. We will produce color swatches using our painting or PVD process for your approval before production.

Q3: What is the process for developing a completely custom cap design?

A: The process is collaborative:

NDA & Briefing: Sign a confidentiality agreement and share your concept.

3D Design & Quote: Our or your designers create technical 3D renderings and mockups for free, then detailed quote.

Prototype & Approval: produce physical prototypes (3D printed or soft-tooled) for fit and form approval for free.

Tooling & Golden Sample: Upon prototype approval, we proceed to hard tooling and produce the official Golden Sample for final sign-off.

Mass Production & Inspection: Full-scale production begins, followed by our 100% inspection before shipment.

Q4: How do you guarantee the longevity of the cap’s finish, especially against perfume leakage?

A: Our 90-day immersion test in aggressive solvents (95% ethanol and concentrated fragrance oils) validates liner and seal integrity. For finishes, we select coatings specifically for chemical resistance. PVD, for instance, provides an inert, impervious barrier that is far superior to standard plating for long-term exposure.

Q5: What are your sustainable or eco-friendly cap options?

A: We offer several solutions:

Materials: Caps from post-consumer recycled (PCR) plastics, FSC-certified woods, and biodegradable biopolymers.

Processes: Factory is ISO 14001 certified, utilizing closed-loop water systems and solar power where feasible.

Design: Advise on designs that use less material without compromising structure.

Share Your Ideas Or Design Files

Our team deeply understands the dreams and challenges of a fragrance entrepreneur, not a simple perfume packaging wholesaler, but a strategic partner focused on providing complete packaging solutions—from concept to shelf for emerging and growing perfume brands.

Ready to engineer the perfect closure for your fragrance?

Let’s try to make miracles together!